Screw pumps

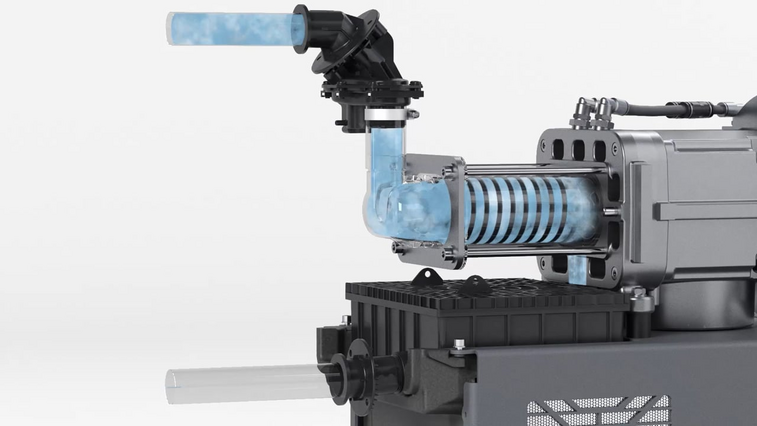

The VACUU·PURE® dry screw pump is ideal for clean processes in the pressure range down to 10-3 mbar. The screw pump is 100% oil-free, generates no abrasion and has no wear parts. VACUU·PURE 10C is chemically resistant against aggressive media.

Vacuum Pump

Selection Guide

Do you have any

questions?

VACUU·PURE® screw pump

Clean and oil-free in the 10-3 mbar range

The VACUU·PURE dry screw pump is ideal for clean processes in the pressure range down to 10-3 mbar. It runs 100% oil-free and does not generate any abrasion. VACUU·PURE is ideal for clean processes that require dry and hydrocarbon-free vacuum. In addition, the screw pump has no wear parts. This means that there are no process interruptions due to changing oil or wear parts.

VACUU·PURE 10C

Chemically resistant - even with aggressive media

The chemically resistant VACUU·PURE 10C screw pump is designed for pumping aggressive gases and vapors. A cold trap is no longer required for the majority of applications.

All wetted materials inside the vacuum pump are made of chemically resistant materials.

VACUU·PURE 10

Pure vacuum for non-corrosive media

VACUU·PURE 10 is ideal for clean processes that require dry and hydrocarbon-free vacuum. As a dry backing pump for turbomolecular pumps, VACUU·PURE offers very good ultimate vacuum.

Gauges & controllers

Measure and control down to 10-3 mbar

To match your screw pump, we offer you the VACUU·VIEW extended gauge and the versatile VACUU·SELECT® vacuum controller, first-class products for vacuum measurement and control in the range down to 10-3 mbar.

Downloads

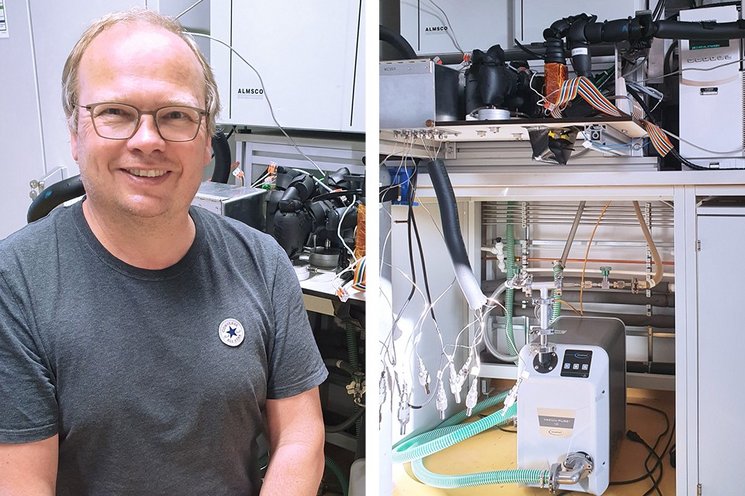

Expert from the 'Schlenk Line Survival Guide' expresses enthusiasm

Dr. Andryj Borys has a bit of a reputation as a “Schlenk Line king”. This is because of his personal blog "Schlenk Line Survival Guide“, where he shares valuable advice from his own laboratory practice. Thousands of followers meanwhile follow him on social media and benefit from his clear instructions and tips. As a student and…

Goethe University Frankfurt uses VACUU·PURE® 10 screw pump

ETH Zurich relies on abrasion-free VACUU·PURE® screw pump

VACUU·PURE® supplies several chemical synthesis hoods at the Max Planck Institute

FAQ

No particles or dust may enter the VACUU·PURE. We therefore recommend the use of suitable measures in these cases, e.g. filters at the inlet. We will be happy to advise you on this.

The VACUU·PURE can be rinsed with distilled water to remove residues inside the pump. This process is described in the operating instructions and can be repeated several times if necessary.

The inlet and outlet can be cleaned by hand with a lint-free cloth soaked in a cleaning agent when the pump is switched off.

The maximum inlet pressure for water vapor with the VACUU·PURE 10C is very high. Water vapor with pressures of up to 300 mbar can be pumped without any problems, even continuously.

The robustness of the VACUU·PURE against water vapor and condensate is also demonstrated during flushing with liquid water. Damage caused by condensate cannot occur (unlike with rotary vane pumps, for example).

In applications with large amounts of condensate, the chemical-resistant VACUU·PURE 10C should always be used.

Light gases (especially helium) can be pumped very well with a VACUU·PURE 10C in the fine vacuum range up to 1 mbar. The sealing gas used with a VACUU·PURE 10C acts as a carrier gas in this instance. The VACUU·PURE 10 model is not suitable for pumping larger quantities of light gases due to the lack of sealing gas.

VACUU·PURE has the Modbus RTU interface, which can be used for external remote control or for integration into automation systems. The Communication Kit is required for this. For example, a VACUU·PURE can be started and stopped, the operating status monitored and connected measuring devices read via the interface. Other VACUU·BUS accessories can also be connected.

The VACUU·PURE is very low-vibration in normal operation. Vibrations are transmitted only slightly from the inlet flange, which is the direct connection to the application. For this reason, VACUU·PURE is ideal for vibration-sensitive applications. If you have any further questions, we will be happy to help you.

The inlet flange can be fitted in four different orientations. This allows a hose to be optimally connected to a VACUU·PURE. The necessary steps are explained in the operating instructions.