DAkkS Accredited calibration laboratory for vacuum technology at VACUUBRAND

Why is the calibration of vacuum gauges important? And is it sufficient to calibrate in-house yourself? Quality management or test equipment monitoring demand that vacuum gauges also be verifiably traceable to national standards. To meet this challenge, we at VACUUBRAND have been operating a calibration laboratory accredited by the German National Accreditation Body (DAkkS) for over 20 years and are a member of the German Calibration Service (DKD).

Latest accreditation certificate according to the standard DIN EIN ISO/IEC 17025:2018

Calibration of test equipment is an essential part of a modern test equipment management system. To ensure high-quality measurements on products and processes, the test equipment itself, such as vacuum gauges, must also be calibrated regularly. This includes their function and accuracy as well as the documentation of the test results in a calibration certificate.

As one of only four accredited calibration laboratories for vacuum technology in Germany, VACUUBRAND is permitted to issue official calibration certificates. We offer the calibration service not only for vacuum gauges from our own production range, but also for gauges from other manufacturers. This service is important for customers, for example, in order to meet the requirements of quality management (DIN EN ISO 9001) or test equipment monitoring. VACUUBRAND's current accreditation for the calibration of vacuum gauges in the measuring range from 10-3 mbar to 1300 mbar is based on the latest standard DIN EN ISO/IEC 17025:2018.

Additional advantages of regular calibration are an increase in process reliability and also audit reliability, due to an increasing demand for test equipment monitoring and calibration certificates during ISO 9001 audits in recent years. Furthermore, calibrated measuring instruments lead to an increase in quality in production or in analyses in the laboratory as well as to a reduction in rejects and rework.

"The calibration service for vacuum gauges is an important part of our quality promise. During the calibration process of the vacuum gauges, the deviation of the measurand from the values specified by higher level standards is determined. The measured values are then documented in the calibration certificate, including the measuring uncertainty. The calibration certificate is recognized worldwide by multilateral agreements through the European co-operation for Accreditation (EA)," explains Dr. Jürgen Breitenbach, Head of the calibration laboratory at VACUUBRAND.

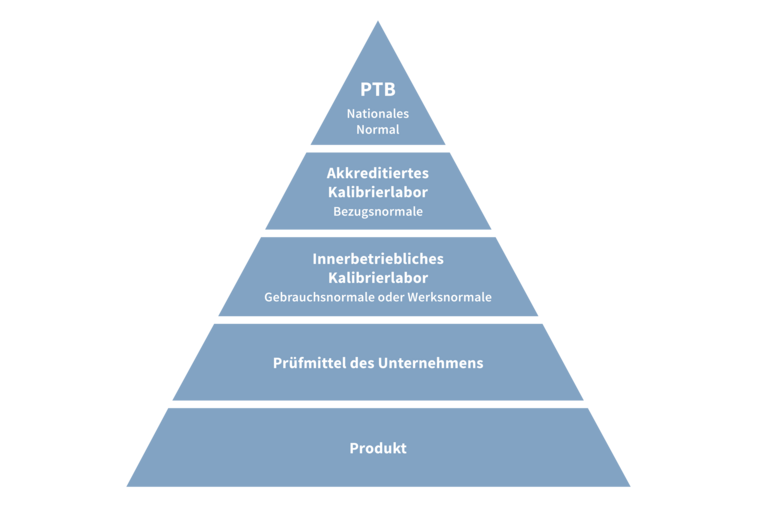

Calibration hierarchy in Germany

Accredited calibration laboratory

If a company's vacuum gauges are to be reliably calibrated, the traceability of the unit pressure to national or international standards is mandatory. In Germany, the Physikalisch-Technische Bundesanstalt (PTB) is the supreme technical authority for metrology. It preserves and develops the national standards for the representation of the SI units – such as the unit Pascal for the physical quantity pressure – and ensures comparability within the international framework through cooperation with other state institutes. The dissemination of this physical unit is done through a chain of comparison measurements starting from the national standard.

DAkkS-accredited calibration laboratories such as VACUUBRAND's are located directly below the PTB in metrological terms. They are subject to DAkkS monitoring and have high-quality standards and measuring equipment that are usually calibrated at PTB. Therefore, DAkkS-accredited testing laboratories fully meet the requirement to calibrate test equipment in a traceable manner.

Companies with an in-house calibration laboratory – which therefore calibrate their vacuum gauges themselves – would have to perform traceability, measurement uncertainty calculations and standard conformity independently. For this purpose, companies often use the services of DAkkS calibration laboratories. As a result, companies' test equipment is also traced back to the national standard through reliable calibration in this chain.

DAkkS calibration certificate with information on measurement results, procedures and performance

DAkkS calibration certificate for reliable measurement results

DAkkS calibration certificates are internationally valid and serve for the complete and comprehensible documentation of all relevant data and results. The calibration certificate contains information on the calibration procedure and the calibration performance as well as measurement results with indication of the measurement uncertainty. The measurement uncertainty identifies the range within which the true value lies with a defined probability. This provides valuable information about the quality and reliability of the measurement results.

Advantages of the VACUUBRAND calibration service

The benefits of our calibration laboratory at VACUUBRAND, which is approved by the German National Accreditation Body (DAkkS) for qualified measurements speak for themselves:

Validity

- Latest accreditation according to DIN EN ISO/IEC 17025:2018

- International recognition and validity through agreements of EA (European co-operation for Accreditation) and ILAC (International Laboratory Accreditation Cooperation)

Experience and methodology

- Many years of experience and competence in calibrating vacuum gauges

- Measurement and analysis methods conforming to standards

- Recognized methods for the determination of measurement uncertainties

Measurements and documentation

- Functional test of the measuring devices

- Traceability to a national or international standard ensured

- Calibration fully documented by DAkkS calibration certificate

- Replacement of wear parts, cleaning and repair of the measuring equipment as required

For all important measurements, you need a calibrated device. A DAkkS-accredited calibration laboratory meets the high demands of calibration and, thanks to an official calibration certificate, creates great confidence in the measuring equipment.