Reactors and synthesis

Exclusion of oxygen, extraction of solvents, pumping of gases or pressure as a reaction condition - our oil-free and chemically resistant vacuum pumps offer the best conditions for reactors and synthesis processes.

Vacuum for reactors and synthesis applications

Oil-free, chemically resistant, powerful

Depending on the process, vacuum is required for various purposes in reactors and synthesis processes. These include the exclusion of oxygen, the extraction of solvents, the pumping of gases or the lowering of pressure as a reaction condition. The requirements for the ultimate vacuum of the pump vary accordingly.

As aggressive media are often used, we recommend chemically resistant vacuum pumps. Oil-free pump technologies offer the advantage that there are no process interruptions due to oil changes and process contamination due to oil vapors is avoided.

These requirements are met by chemistry diaphragm pumps for the pressure range down to 1 mbar and the chemistry screw pump for the range down to 10-3 mbar. Both pump types can be used for volumes of up to 200 liters. Our modular VAC 24seven process system is suitable for much larger volumes. It is based on the technology of the VARIO chemistry diaphragm pumps.

Important questions on vacuum technology

Depending on the process, vacuum is required for various purposes in reactors and synthesis processes. These include the exclusion of oxygen, the extraction of solvents, the pumping of gases or the lowering of pressure as a reaction condition. The requirements for the ultimate vacuum of the pump vary accordingly. As aggressive media are often used, we recommend chemccally resistant vacuum pumps. Oil-free pump technologies offer the advantage that there are no process interruptions due to oil changes and process contamination due to oil vapors is avoided.

These requirements are met by chemistry diaphragm pumps for the pressure range down to 1 mbar and the chemistry screw pump for the range down to 10-3 mbar. Both pump types can be used for volumes of up to 200 liters.

Our modular VAC 24seven process system is suitable for much larger scales. It is based on chemistry diaphragm pump technology.

The question of the ultimate vacuum cannot be answered in general terms, as it depends heavily on the process. Our experts will be happy to advise you individually.

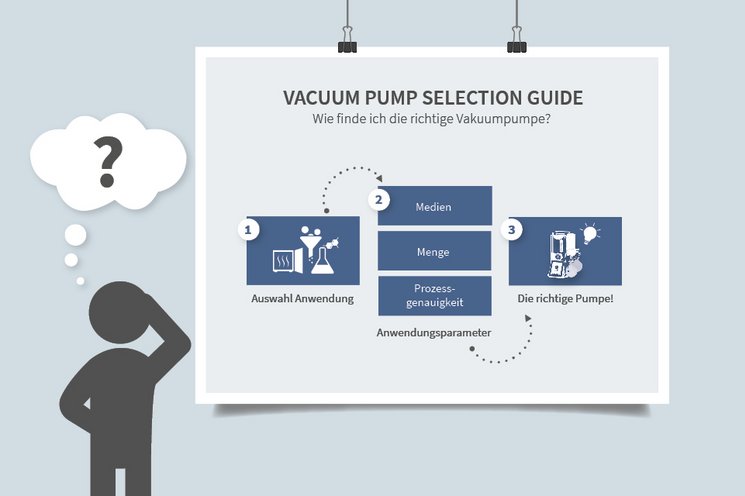

The pumping speed is designed based on the sample quantity. In our Vacuum Pump Selection Guide you will find suitable product suggestions for reactors and synthesis applications.

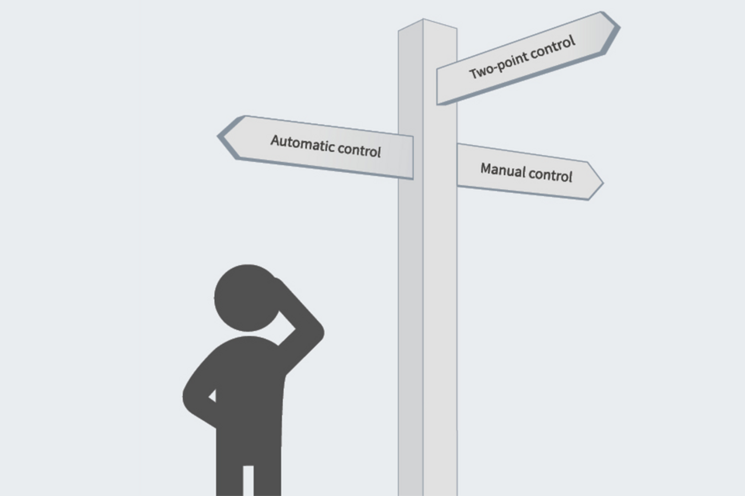

find pumpOur vacuum pumps can also be used with existing vacuum control systems without any problems.

In addition to precise vacuum control, the VACUU·SELECT vacuum controller offers additional advantages for individual vacuum processes. With the application editor, you can easily define and save parameters such as pressure, time or pump-down speed.

With classic two-point control, a vacuum valve is switched to keep the vacuum within the target pressure range. VARIO diaphragm pumps control the vacuum precisely via the motor speed. This more precise control leads to optimum evaporation rates and up to 30 % shorter process times. It also makes the pump whisper-quiet, reduces energy consumption and vibration and extends the service life of the diaphragms.

An emission condenser (EK) at the outlet enables almost 100 % solvent recovery. A separator (AK) on the inlet side protects the pump by collecting condensate and retaining droplets and particles.

The recommended vacuum pumps include designs with a hose nozzle connection and designs with a small flange connection. There are also different designs and connections on the application side. For this reason, it is not uncommon for the pump and reactor connections to differ. We offer suitable tubing and accessories for such cases.