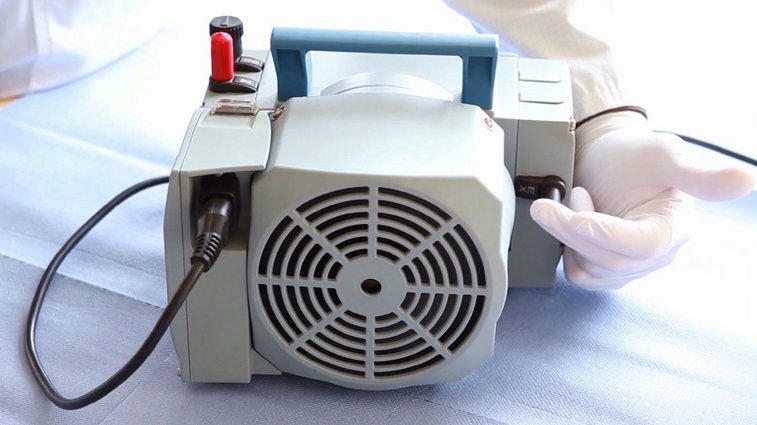

Function test using the example of the diaphragm pump MZ 2C NT

Laboratory processes are only successful if important process conditions, such as the required process pressure, are achieved. The most important indication for the proper function of a vacuum pump is its ability to reach its specified final pressure, or ultimate vacuum. This can be determined with a calibrated gauge to measure the pump’s ultimate vacuum. If no such gauge is available, users can perform an initial function test. This is an indication of whether the vacuum pump can reach its specified final pressure. Here, we are showing a functional test using the example of the MZ 2C chemistry diaphragm pump.

What is the function test for?

The function test is a quick and easy way to check the pump if leakage or loss of vacuum is suspected when no vacuum gauge is available. It is an indicator of whether the valves and diaphragms in a diaphragm pump are intact.

How do I carry out the function test?

No special tools are required for a quick functional test of a diaphragm pump. It is advisable to wear gloves and safety goggles to protect yourself. The function test of the diaphragm pump takes only a few minutes.

- Disconnect the diaphragm pump from the application

- Close the inlet and gas ballast

- Switch on vacuum pump

- Check the outlet to determine if a significant gas flow can be felt

- If there is no significant gas flow, the vacuum pump is ok; check the application and connections for possible leaks

- If there is significant gas flow, replace the wear parts of the diaphragm pump

For a more precise vacuum test we recommend an appropriate measuring device, such as the DVR2 pro for diaphragm pumps or the VACUU·VIEW extended for rotary vane pumps.