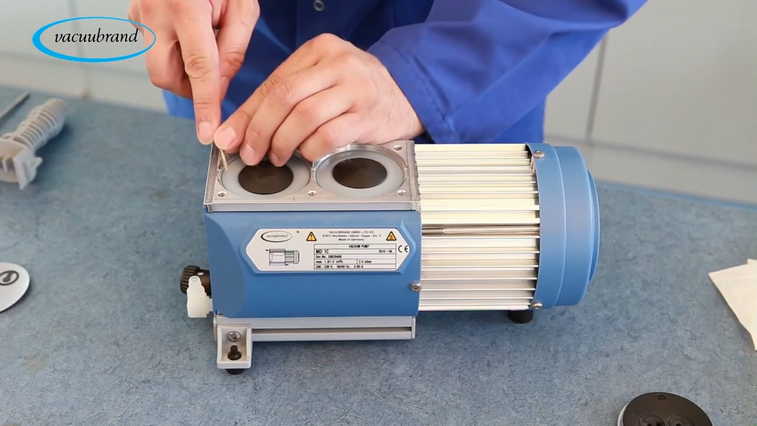

Changing diaphragms and valves using the example of the MD 1C chemistry diaphragm pump

Vacuum pumps should reliably support important processes in the background and take up as little of your time as possible for maintenance. We explain how to change diaphragms and valves using the example of the MD 1C chemistry diaphragm pump. Apart from wear parts, the diaphragm pump runs maintenance-free under normal load. All bearings are lubricated for life.

Why a diaphragm/valve change?

Even with proper operation, diaphragms and valves wear out over time. Wear can be accelerated by the accumulation of liquids and dust particles. This can impair the pumping speed (flow) and, ultimately, the pump’s ultimate vacuum. Regular maintenance can not only increase the service life of the vacuum pump, but also provide better protection for people and the environment.

Which tools are required for this?

You can find the full list in the pump manual. For the MD 1C pump, see here.

For the maintenance of the MD 1C diaphragm pump, you will need the following tools:

- Diaphragm key (width 46 mm)

- Open end wrench (width 14/17 mm)

- Allen key (4 mm)

- Phillips screwdriver (size 2)

- DVR2 pro Vacuum gauge

What else needs to be considered?

Before maintenance the diaphragm pump must be disconnected from the electrical outlet. Then the user should wait five seconds until the capacitors have discharged before working on the pump. Now allow the pump to cool down. For safety, personal protective equipment should be worn when working on the pump. To avoid mixing up components, only the pump heads of one pump side should be disassembled at a time. Contamination can be removed with a suitable cleaning agent.

How long does the process take?

In our example of the MD 1C vacuum pump, we should plan on about 1.5 hours. Depending on pump type and size, number of pump heads, accessories and degree of contamination, a diaphragm and valve change can take between 30 minutes and several hours.

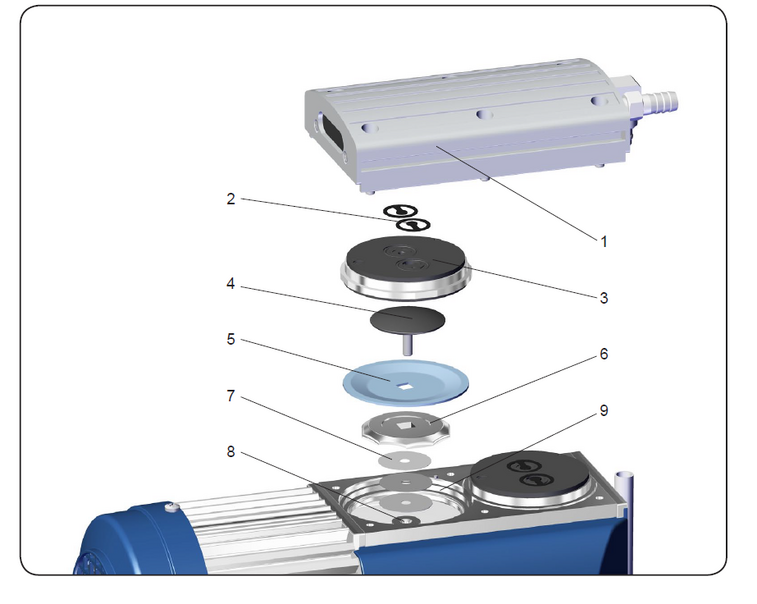

Diaphragm (5) and valves (2) inside the vacuum pump MD 1C

How often should the diaphragms/valves be changed?

The typical service life of diaphragms and valves is 15,000 operating hours. When corrosive gases and vapors are pumped, deposits can form in the pump, which affect the wear of the valves and diaphragms. In this case, these maintenance operations should be carried out more frequently – depending on the user's experience. At minimum, when the deepest achievable vacuum level diminishes (i.e., the absolute pressure level goes up), or when the pump’s noise level increases, the pumping chamber, the diaphragms and the valves should be cleaned; and diaphragms and valves should be checked for cracks.

Video: Changing diaphragms and valves using the example of the MD 1C chemistry diaphragm pump

What are the individual steps?

For a quick start watch our video about the MD 1C.

For proper procedure, please also read the operating instructions.

Depending on the pump type, other work steps may be necessary.