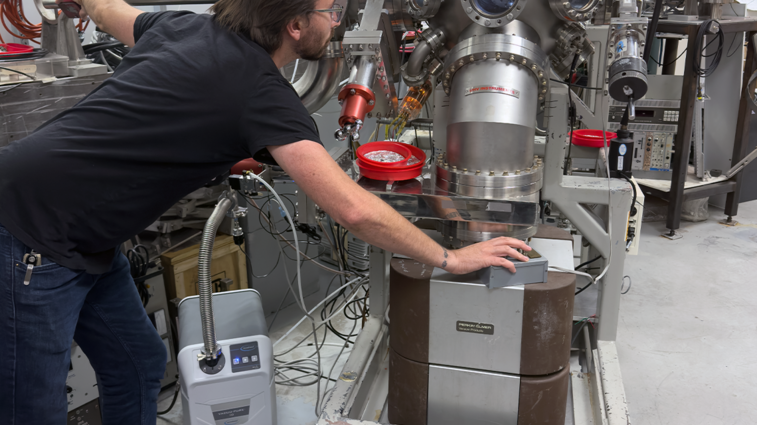

RBS Endstation with VACUU∙PURE 10® vacuum pump

© Mark Mangus – IBeAM laboratory at Arizona State University

The Ion Beam Analysis of Materials (IBeAM) laboratory at Arizona State University is always in search of ways to upgrade their equipment. It is part of the Eyring Materials Center, whose research specialist principal is Mark Mangus. He works closely with students and industry partners to train on the use of the equipment and data reduction, and is tasked with maintaining the equipment. This customer story investigates the technical details and benefits of using the VACUU∙PURE® 10 vacuum pump in the university's particle accelerator.

Mangus explains, “I’m looking for the next upgrade, because really if I’m fixing it, then I’m not training students or other researchers, or working on other things I can make more robust.” One upgrade Mangus wanted to evaluate is to identify a lower-maintenance roughing pump for the particle accelerator.

Any new roughing pump would still need to provide reliable, stable, and low-vibration vacuum to achieve optimal vacuum conditions for particle accelerator experiments. Mangus assessed a VACUUBRAND VACUU∙PURE® 10 screw pump as an alternative to oil-sealed rotary vane pumps and found that it offered comparable performance to traditional rotary vane pumps without the need for oil changes and rebuilds.

General requirements for high vacuum applications

- Reliability: Minimizing downtime is crucial for maximizing experimental productivity and reducing maintenance costs.

- Deep, stable vacuum: The particle accelerator requires a stable 10-3 torr (mbar) vacuum from the roughing pump to achieve consistent vacuum levels as low as 10-9 torr (mbar) with the turbo pump.

- Low Vibration: Minimizing vibration ensures the stability of sensitive equipment and improves the reproducibility of experimental data.

Particle accelerator application

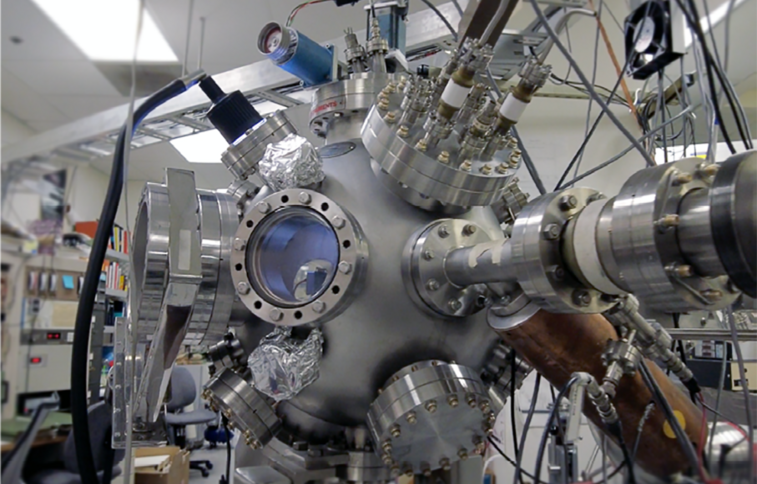

IBeAM

© William Hollander - ASU Core Facilities Marketing

The particle accelerator in the IBeAM lab is a 1.7 MeV Tandetron Ion Accelerator. It facilitates various experiments under the umbrellas of ion beam analysis (IBA) and ion beam modification of materials (IBMM). Some of the unique applications include:

- Chemical composition analysis of current and next generation thin films for semiconductor applications.

- Particle (ion) induced x-ray emission (PIXE) for chemical analysis of cultural heritage artifacts including Roman-era death masks, ancient pottery and statues and metals used in ancient weapons with end goals being authentication and determining ancient trade routes.

- Particle (ion) induced gamma emission (PIGE) for isotope analysis of Lithium and other elements used in energy applications.

Rotary vane, scroll or screw pump?

Oil-free VACUU∙PURE® 10 screw pump with no wear parts

The particle accelerator’s analytical chamber operates in the high vacuum range (10-7 to 10-8 torr). The load lock, used to transition samples and equipment into the analytical chamber, is pumped down to a relative foreline pressure of approximately 50 millitorr (0,07 mbar) using the roughing pump. The turbo pump is then engaged to bring the load lock down to 10-6 – 10-7 torr. The turbo pump used is rated for up to 260 l/s. An oil-sealed rotary vane pump with a rated pumping speed of 14.2 m3/hr. and an ultimate vacuum of 2 x 10-3 mbar (1.5 x 10-3 torr) had been used until recently.

The rotary vane pump was replaced with the VACUU∙PURE 10 pump to assess the feasibility of a low-maintenance roughing pump. The VACUU∙PURE 10 pump has a rated pumping speed of 10 m3/hr. and an ultimate vacuum of 5 x 10-3 mbar (3.8 x 10-3 torr). The process of evacuating the load lock from atmospheric pressure to the relative foreline pressure of approximately 50 millitorr (0.07 mbar) took roughly 6 minutes with the rotary vane pump. A comparable pump down time was achieved using the VACUU∙PURE 10 pump. When the gate valve isolating the load lock from the analytic chamber is opened, a pressure rise of less than one order of magnitude has been observed when the VACUU∙PURE pump has been used as the roughing pump.

Mangus also briefly considered scroll pumps as an alternative to the incumbent rotary vane pumps. However, a cursory evaluation of the relative price, maintenance requirements, and ultimate vacuum of the most comparable scroll pumps on the market revealed that the VACUU∙PURE 10 pump and the incumbent rotary vane pump both offered superior value to the scroll pump. Having made the determination that the value proposition for scroll pumps in his application was at best marginal, Mangus considered only the VACUU∙PURE 10 pump as a viable replacement for the rotary vane pump.

Ultimately, Mangus determined that the VACUU∙PURE 10 pump provides comparable pump performance with the potential for the benefits of a low maintenance roughing pump. Rotary vane pumps require frequent oil changes and Mangus was sending his rotary vane pumps out for rebuild roughly every two years, demanding significant time and resources. This also has the effect of limiting the time that the particle accelerator can be used for research by students and ASU’s industry partners.

Conclusion

The integration of the VACUU·PURE 10 pump has met the stringent requirements of reliability, stability, and low vibration in the IBeAM laboratory at Arizona State University. By offering comparable performance to traditional pumps while eliminating the need for oil changes, the VACUU·PURE 10 has enabled more efficient research processes and enhanced collaboration opportunities with students and industry partners.