Lyophilization

To completely avoid melting processes, the vacuum pump must quickly reach a low target pressure. Sufficient pumping speed is therefore important. An ultimate vacuum in the range of 10-3 mbar is required for residual drying.

Webinar: vacuum for lyophilization

Vacuum for lyophilization

Low ultimate pressure and high pumping speed

For sublimation - the direct transition from a solid to a gaseous aggregate state - a pressure in the fine vacuum range well below 1 mbar is usually required. In order to prevent the samples from melting in the meantime, it is essential to rapidly reduce the pressure to the target pressure. A high pumping speed of the vacuum pump is therefore very important.

For high degrees of drying, residual drying with the lowest possible ultimate vacuum in the range of 10-3 mbar is necessary. If solvents are used, the use of corrosion-resistant vacuum pumps such as the chemistry screw pump or the chemistry-HYBRID pump is recommended.

Important questions on vacuum technology

Lyophilization requires a vacuum pump with ultimate vacuum in the fine vacuum range (1 to 10-3 mbar). To prevent the samples from melting in the meantime during primary drying, it is essential to quickly lower the pressure to the target pressure. For this, the pump requires a high pumping speed. The lowest possible ultimate vacuum is crucial for residual drying.

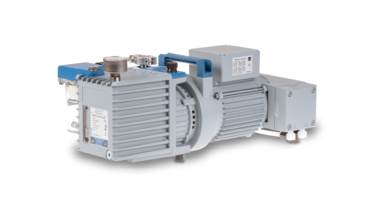

These requirements are met by two-stage rotary vane pumps, the chemistry-HYBRID pump and the VACUU·PURE screw pump. For use of solvents, the chemistry-HYBRID pump offers better protection against corrosion than a rotary vane pump.

The VACUU·PURE 10C chemistry screw pump provides the best chemically resistance. The screw pump is also 100 % oil-free and has no wear parts. There is no need to change oil or wear parts. The integrated regeneration mode allows the pump to dry quickly at the end of the process, enabling a higher sample throughput compared to other pump technologies.

The target pressure for primary drying varies depending on the medium. In most cases, however, it is below 1 mbar. For residual drying, the lowest possible ultimate vacuum is crucial. We therefore recommend vacuum pumps with an ultimate vacuum in the range of 10-3 mbar for lyophilization.

For an optimal process flow, it is important that the sublimation rate of the samples and the resublimation at the ice condenser are as balanced as possible. When designing the pumping speed, we use the capacity of the ice condenser as a guideline.

In our Vacuum Pump Selection Guide you will find suitable product suggestions for your lyophilisation requirements:

Yes, changing the pump type is possible at any time.

For optimum performance, rotary vane pumps, chemistry-HYBRID pumps and screw pumps should warm up for approx. 30 minutes before starting the process. After operation, rotary vane pumps and chemistry-HYBRID pumps should run for a further 30 minutes with the gas ballast open in order to discharge any condensate. The VACUU·PURE screw pump has an integrated regeneration mode for drying.

Always ensure that the inlet to the freeze dryer is closed during warm-up and after-running.

All useful tips for operating your vacuum pump can be found here:

The vacuum pumps we recommend all have a small flange connection.

On the lyophilization side, there are designs with a hose nipple connection and designs with a small flange connection in different sizes. For this reason, it is not uncommon for the pump and lyophilization connections to differ. We offer you the right tubing and the necessary connection materials for all cases.

In our Connection Guide, you will find everything you need to know to connect your vacuum pump to a freeze dryer.